Manufacture of machinery and robotics

The Machinery Production Department, which is part of the Mechatronics Division, was established in 2004 and is part of ELVAC, a.s. It deals with commercial-technical and engineering-supply services in the field of industrial automation.

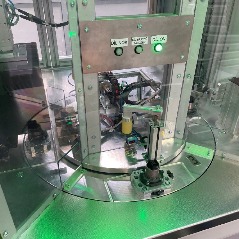

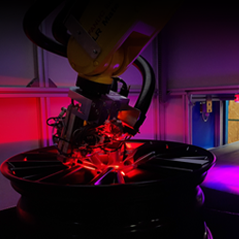

In our plants in Ostrava and Holešov we produce mainly single-purpose machines, assembly lines, punching units under the press and various robotic cells.

HOW IS THE MACHINE PRODUCED?

Designing a new solution is the most complex process of the entire automation solution. We know that a quality design at the very beginning always pays off at the end of the project by minimizing additional costs.

Successful design is achieved by processing process analysis, risk analysis and virtual model design, using Autodesk Inventor, Visual Components or WinMOD software.

We further optimize the model in terms of function, operation, performance, material flow, etc.

For the final visualization, we prepare the design of robots, drives, sensors, control systems, cameras and the overall concept of electrical equipment including all safety functions.

Our team of engineers and designers then transforms the design into detailed production documentation for machine manufacturing, switchboard production, electrical assembly and programming of the control system with robots, controlled drives, cameras, etc.

We assemble machines in our own assembly halls in Ostrava and Holešov.

The next phase of the project belongs to our team of programmers. Based on the 3D model, electrical design and functional description, they have already prepared the application software for PLC (automatic control unit), operator HMI panels and stations. The goal is to have clear push-button control on all counters, HMI panels and operator SCADA stations that provide the operator with important detailed status and fault messages for easy and fast machine diagnostics.

Before the real commissioning phase begins, we perform virtual commissioning with a prepared simulation and virtual twin, where we test and verify the basic correct functioning of the application software with high efficiency and can test almost all critical conditions without risk of damaging the machine.

After completing the real machine, we start with the classical phase of the project, the so-called commissioning, at the end of which we have a tested and fully functional machine that is ready for pre-series production.

Only a fully functional and tested machine or line is taken to the customer for installation. A team of mechanics and electrical fitters under the supervision of the project manager will prepare the machine for transport. The customer will then have the machine set up, wired and prepared for the arrival of our programmers. In this last phase, we will debug the machine under series production conditions to verify the final production quality, machine reliability and the required cycle time to achieve the planned production capacity. Production can begin.

The delivery of a new machine or line is most often associated with a 2-year warranty period on the complete delivery.

We also offer post-warranty service based on service contracts.

HOW IS THE MACHINE PRODUCED?

Designing a new solution is the most complex process of the entire automation solution. We know that a quality design at the very beginning always pays off at the end of the project by minimizing additional costs.

Successful design is achieved by processing process analysis, risk analysis and virtual model design, using Autodesk Inventor, Visual Components or WinMOD software.

We further optimize the model in terms of function, operation, performance, material flow, etc.

For the final visualization, we prepare the design of robots, drives, sensors, control systems, cameras and the overall concept of electrical equipment including all safety functions.

Our team of engineers and designers then transforms the design into detailed production documentation for machine manufacturing, switchboard production, electrical assembly and programming of the control system with robots, controlled drives, cameras, etc.

We assemble machines in our own assembly halls in Ostrava and Holešov.

The next phase of the project belongs to our team of programmers. Based on the 3D model, electrical design and functional description, they have already prepared the application software for PLC (automatic control unit), operator HMI panels and stations. The goal is to have clear push-button control on all counters, HMI panels and operator SCADA stations that provide the operator with important detailed status and fault messages for easy and fast machine diagnostics.

Before the real commissioning phase begins, we perform virtual commissioning with a prepared simulation and virtual twin, where we test and verify the basic correct functioning of the application software with high efficiency and can test almost all critical conditions without risk of damaging the machine.

After completing the real machine, we start with the classical phase of the project, the so-called commissioning, at the end of which we have a tested and fully functional machine that is ready for pre-series production.

The next phase of the project belongs to our team of programmers. Based on the 3D model, electrical design and functional description, they have already prepared the application software for PLC (automatic control unit), operator HMI panels and stations. The goal is to have clear push-button control on all counters, HMI panels and operator SCADA stations that provide the operator with important detailed status and fault messages for easy and fast machine diagnostics.

Before the real commissioning phase begins, we perform virtual commissioning with a prepared simulation and virtual twin, where we test and verify the basic correct functioning of the application software with high efficiency and can test almost all critical conditions without risk of damaging the machine.

After completing the real machine, we start with the classical phase of the project, the so-called commissioning, at the end of which we have a tested and fully functional machine that is ready for pre-series production.

The delivery of a new machine or line is most often associated with a 2-year warranty period on the complete delivery.

We also offer post-warranty service based on service contracts.

Contact us

Are you interested in any solutions in the field of machine manufacturing and robotics? We would be happy to discuss your requirements and propose the ideal solution. Do not hesitate to contact us to find out more about the possibilities of cooperation.

OUR PRODUCTS AND SERVICES

WHY CHOOSE

PROFESSIONALISM AND EXPERIENCE

Every one of our employees is a professional in their field. Our services and products are the result of the experience and expertise we have accumulated for over 30 years. We are not afraid of challenges and always strive to find solutions that meet all of our customers' demanding requirements.

CERTIFICATION

We hold several quality and safety certificates. In addition, we follow a set of strict internal guidelines designed to maximize the quality and efficiency of our work. All these standards are regularly checked by internal and external audits.

COMPREHENSIVE SOLUTION

The ELVAC Group brings together several companies that, thanks to interdisciplinary cooperation, are able to provide comprehensive solutions for a wide range of industrial applications. We provide services and products that intertwine and complement each other, ultimately making your project easier and saving you costs.